You can take it to the field! Compact and Portable Laser Peening Equipment" Now Available for Hands-on Experience Next Generation Surface Treatment Technology to Innovate Infrastructure Maintenance and Metal Fatigue Countermeasures -- Runs through March 13, 2026

公益財団法人名古屋産業科学研究所

The Nagoya Institute of Industrial Science and Technology (NISI) is holding a hands-on experience of the compact and portable laser peening equipment it is developing as part of the Aichi Prefecture Industry-Academia-Government Collaboration Project "Knowledge Hub Aichi: Priority Research Project Phase V" at the Knowledge Hub Aichi until March 13, 2026.

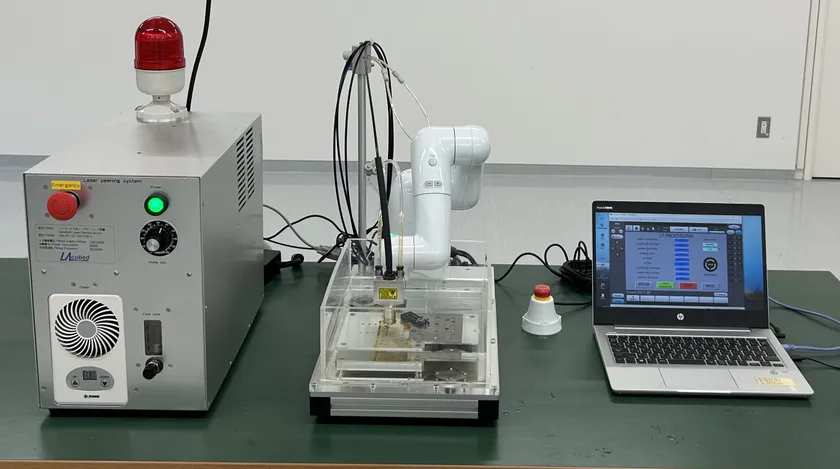

At this hands-on event, visitors will be able to see the latest laser peening equipment, which has been downsized from the large, fixed type of laser peening equipment used in the past to a size that can be brought to the job site for use.

Compact and portable laser peening equipment

Portable" to solve conventional problems

Laser peening is a next-generation surface modification technology that imparts compressive residual stress to metal surfaces by irradiating them with a high-energy laser, which is extremely effective in extending metal fatigue life and reducing component weight.

On the other hand, conventional equipment was large and fixed, limiting its installation location and limiting its application to a limited number of factory facilities.

The newly developed compact and portable laser peening system is "portable size" and can be carried to the work site.

This will greatly expand the range of applications of laser peening technology, enabling not only installation in existing manufacturing lines, but also application to maintenance and repair sites for infrastructure structures such as bridges, piping, and plant facilities, where on-site work is essential.

■Report on Public Event (Materials Available)

This technology has attracted a great deal of attention, and many experts and engineers from Japan and overseas attended the related event held in November 2025, which included a demonstration of the actual equipment.

A report of the event is now available on the web. If you are interested in the event, please refer to the following link.

Industrial Workshop on Compact Laser Peening Technology] (Japanese)

Conducted for engineers in Japan

The report of the workshop is here: https://peatix.com/event/4818982/view

LSP International Symposium Aichi, Japan

International Symposium

The report of the symposium is here: https://peatix.com/event/4807945/view

Experience with actual equipment

I want to confirm actual workability.

We would like to examine the applicability to our own materials.

For such companies and research institutes, we are offering hands-on experience of actual equipment on an individual basis until March 13, 2026.

Please come and experience the world's most advanced portable surface treatment technology.

Please note that we may not be able to meet your request depending on the operating conditions of the equipment and the content of the event.

Application and Inquiries

Nagoya Institute of Industrial Science and Technology Chubu TLO

Contact : Fujikawa

E-mail: fujikawa@nisri.jp

Related Links

Aichi Key Research Projects

https://www.astf-kha.jp/project/

Video of the installation of a compact, portable laser peening system

https://youtube.com/playlist?list=PLwqLOTT-AVOSsGUcg9EGgPIN1l14OWwtz&si=HBoXonpnxc8ZCPfh

- Category:

- Services

- Genres:

- Technology General Business Economy(Japan)