The Challenge to Create a Needle that Does Not Damage Cells - ALGOVISION TECHNOLOGIES INC. Algovision Technologies Develops New Technology to Support Regenerative Medicine ~A New Era of Injection Needle Inner Surface Processing

ALGOVISION TECHNOLOGIES INC.

Algovision Technologies Inc. (Headquarters: Kyoto, Japan; CEO: Shoichi Tachibana) has developed a new technology to polish the inner surface of injection needles used in regenerative medicine smoothly, utilizing its main product, the fluid polishing system.

This new technology is expected to further accelerate the practical application of regenerative medicine, as it has revealed the possibility of reducing the risk of cell damage inside the needle, which has been an issue when delivering cells directly into the patient's body.

Details of "Algovision Technologies Inc.": https://algovision.co.jp/en/

Precision pipes for medical use (wire-cut photo)

■Background: The Bottleneck in Cell Therapy is "Inside the Needle

In regenerative medicine, "cell transplantation," in which the patient's own cells or cultured cells are returned to the body, is used to treat myocardial infarction, spinal cord injury, and intractable diseases.

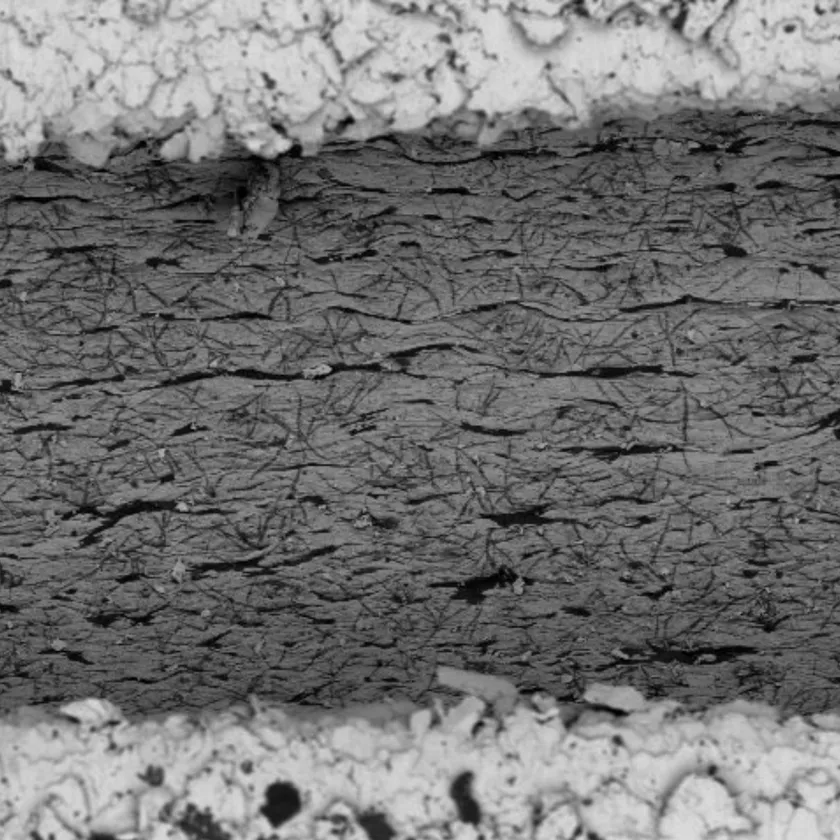

However, the inner surface of conventional injection needles remains microscopically uneven, which can be damaged by friction and pressure when cells pass through it. It has been pointed out that this could reduce the survival rate of important cells used for treatment and affect the effectiveness of treatment.

■Fluid Polishing Realizes "Cell-Friendly Needle

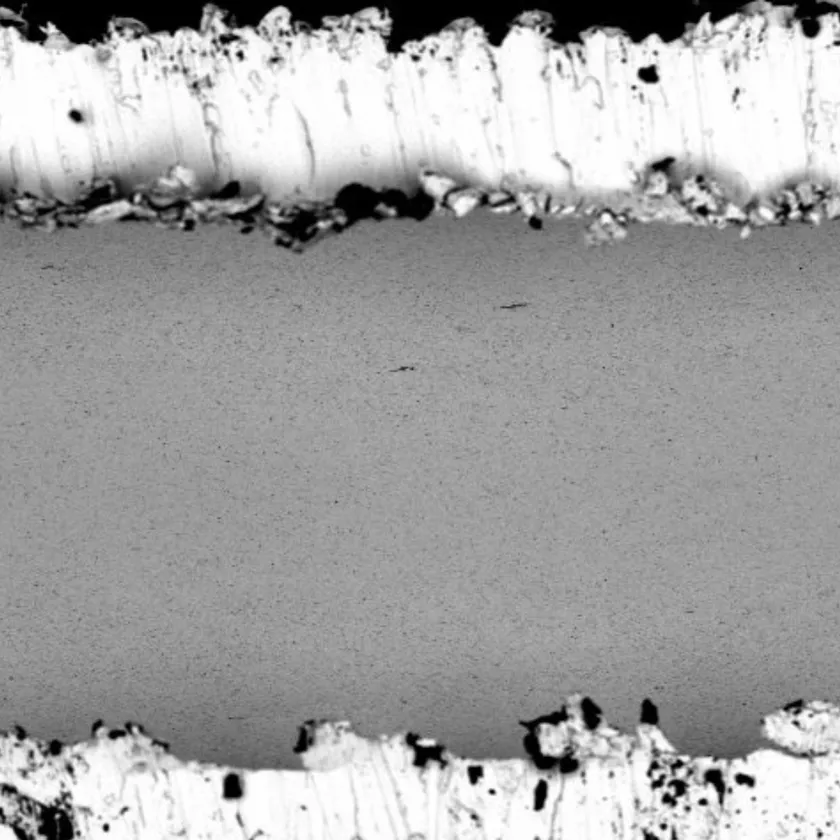

The fluid polishing system technology developed by Algovision Technologies circulates a fluid mixed with water and an abrasive on the inner surface of the injection needle to uniformly polish even nano-level irregularities.

Syringe needles that have undergone this process have the following advantages.

・The inner surface becomes smooth like a mirror, greatly reducing friction.

・The cell survival rate is increased, contributing to the improvement of therapeutic effects.

・Able to supply high quality and stable needles required by medical institutions

The image is not of a rough pipe, but of a glass-like polished pipe through which cells pass, making them less susceptible to damage.

Pipe inner surface (before fluid polishing)

Pipe inner surface (after fluid polishing)

■Impact on Medical and Industrial Applications

This technology is expected to be applied not only to regenerative medicine, but also to injection needles for administering delicate medicines such as anticancer drugs and polymeric drugs, and to other medical device parts such as catheters.

We will accelerate our collaboration with medical and research institutions in the future as a solution to deliver cells and drugs "more safely and reliably" in the medical field.

■Representative Comment

Our fluid polishing technology has been cultivated in the industrial field of automobiles and precision parts. However, it is a great pleasure for us to be able to apply the same technology to "needles that connect lives. We will continue to develop the technology so that it can help support the future of regenerative medicine.

- Shoichi Tachibana, CEO, Algovision Technologies Inc.

■Outline of Technology

Technology name: Fluid polishing

Applicable bore diameter: φ0.1 to φ5.0

Applicable length: up to 2000mm

Applicable materials: Stainless steel (303, 304, 316, 316L, etc.)

Titanium (pure Ti, Ni-Ti, 64Ti, etc.)

Aluminum alloys (A5052, etc.)

Cobalt alloys (Elgiloy, Mp35N, etc.)

Nickel alloys (Inconel, Hastelloy, etc.)

Copper alloys (cu,etc)

Others (S45C, SCM415, etc.)

*Please contact us for sizes and materials not listed above.

■Company Profile

Company name: ALGOVISION TECHNOLOGIES INC.

Representative : Shoichi Tachibana, CEO

Location: 800-1 Kawanishi-cho, Kashihara-shi, Nara 634-0826, Japan (Nara Plant)

Establishment : January 2007

Business : Development of fluid polishing technology and contract polishing

- Category:

- Corporate Trends

- Genres:

- Medical care Technology Economy(Japan)