WEF Technology Development develops an active oxygen catalyst water treatment method capable of high-speed decomposition and sterilization.

Production plants, water treatment plants, and sewage treatment plants can now secure sustainable water resources

WEF技術開発株式会社

WEF Technology Development Co. (Location: Otsu City, Shiga Prefecture; President: Akira Aoyama), which has the world's leading technology for generating large amounts of active oxygen in the atmosphere at low cost, has successfully developed a high-speed organic matter decomposition and sterilization technology that has been a challenge to address wastewater as a resource in preparation for the global water shortages that will become increasingly prominent. The company has succeeded in developing a high-speed organic decomposition and disinfection technology.

What is Needed in Water Treatment Today

The standard activated sludge method of wastewater treatment developed in the U.K. over 100 years ago quickly spread around the world and continues to be the mainstream of wastewater treatment because it does not require any special bacteria, and the bacteria easily decompose contaminants by supplying air.

However, one of the most challenging problems in recent years has been the presence of persistent compounds in wastewater. Conventional activated sludge methods are usually effective in breaking down the contaminants present in wastewater, but they do not remove most of the persistent compounds. This is evidenced by the increase in chemical-laden wastewater in production plants, the increasing number of persistent compounds in agricultural and general wastewater, such as pharmaceuticals, endocrine disruptors, personal care products, and pesticides, and the continuing rise in COD values in lakes and rivers from which drinking water is taken. These are almost always carcinogens and can cause damage to the kidneys, liver, circulatory system, nervous system, and reproductive system.

Sustainable cities in developed countries need clean and safe water to maintain high standards of hygiene and protect people from potential diseases, and developing countries need technology that can instantly disinfect surface water contaminated with pathogens.

It is said that only reactive oxygen species (especially hydroxyl radicals) can treat these persistent compounds, and AOP (Advanced Oxidation Process) treatment methods using ozone and ultraviolet light have been developed. However, AOPs are still not widely used due to their high cost and low amount of hydroxyl radical generation.

What is the AOS treatment?

The reactive oxygen species "superoxide anion" is instantly generated from oxygen in the air by the reactive oxygen generator "AOS. For organic matter decomposition in water, the amount of hydroxyl radicals generated by superoxide anion alone is small, and the organic matter decomposition efficiency is low.

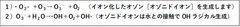

Reactive Oxygen Generation Reaction Formula

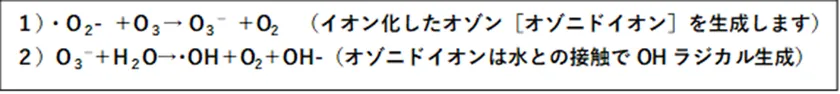

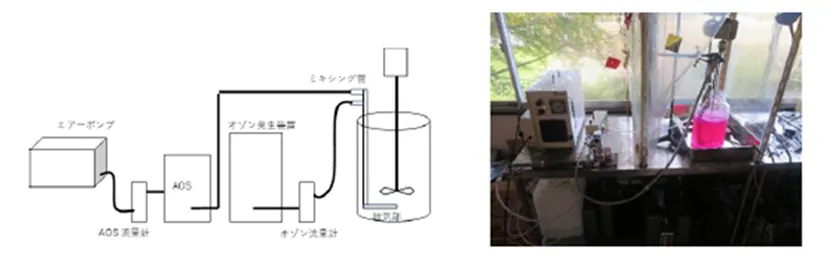

W-Gaia treatment system

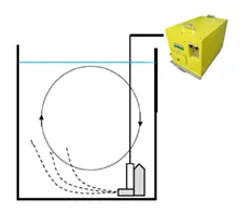

In the specific process, ozonide ions generated by the W-Gaia generator are supplied to the treatment tank in microbubbles to increase contact efficiency, and are converted to OH radicals in contact with pollutants for decomposition.

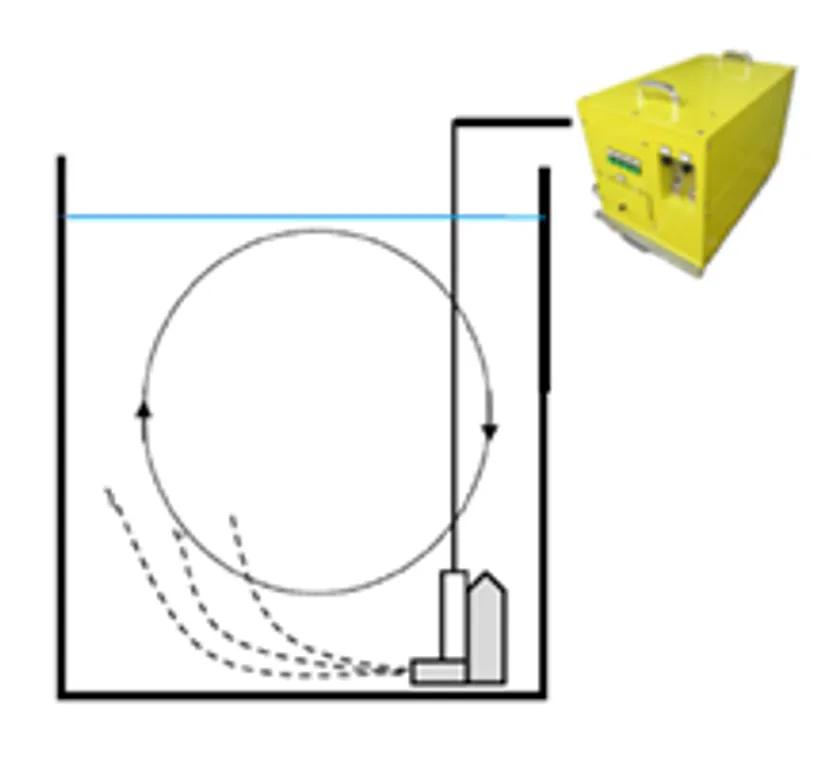

Organic matter decomposition in water

This activated oxygen water treatment system can decompose organic matter in water 2 to 3 times faster than ozone.

Comparison of treatment time by dye treatment

Comparison of treatment effect by decomposition speed of dye Rhodamine (table test scene)

■The world is looking for amazing water treatment technology

As mentioned above, persistent compounds are increasing not only in factory wastewater but also in river water, and the wide range of substances contained and their high concentrations make this an extremely troublesome issue. Furthermore, the emergence of antibiotic-resistant bacteria (ARB) and antibiotic-resistant genes (ARG) has recently become an issue, and alarm bells are ringing about their impact on human and animal health.

In order to solve this situation, we need a treatment technology that can instantly disinfect water, which in the case of water, can change persistent degradation to easy degradation (microorganisms can eat it) in a short period of time.

Development of the world's leading technology "active oxygen catalyst treatment" to solve current water treatment problems

In order to solve the difficult problems surrounding water treatment, we have been working to brush up our already developed active oxygen treatment technology, and have recently confirmed that the treatment effect can be increased more than 10 times by using a special catalyst. We have also studied and demonstrated a method for stable water treatment.

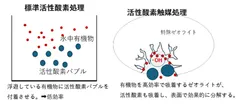

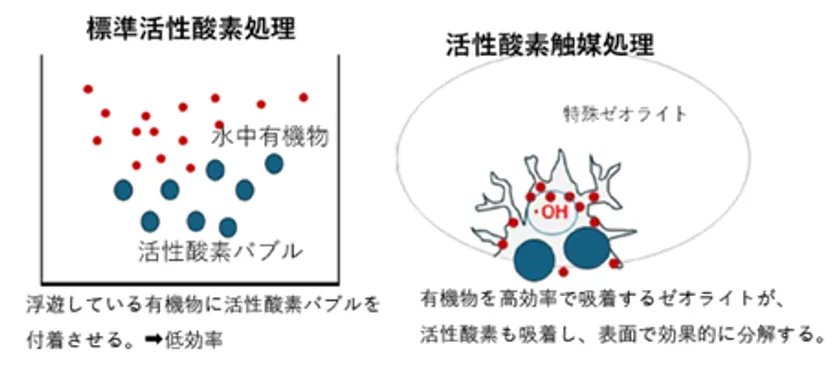

Our AOPs and other activated oxygen treatments decompose contaminants suspended in water by bringing them into contact with floating activated oxygen bubbles, which are also suspended in the water. Since both contaminants are suspended in the water, the contact efficiency is not good.

In general, zeolites are known to adsorb contaminants in water well. If contaminants are adsorbed by zeolite and the adsorbed contaminant bubbles are contacted with active oxygen, a large amount of contaminants can be treated at once. The problem is that zeolite rarely adsorbs reactive oxygen species. In order to adsorb them, synthetic zeolite containing substances that are easily adsorbed is required.

Explanation of catalyst use

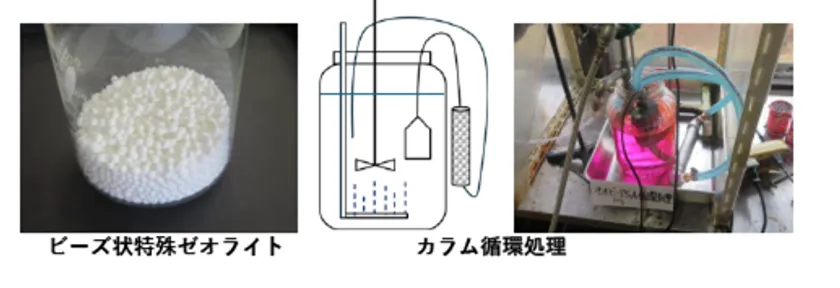

We searched for the zeolite that adsorbs the most reactive oxygen species among the synthetic zeolites on the market.

Comparison with normal treatment

When we added zeolite with excellent adsorption of active oxygen to the treatment, we were able to process the material 10 times faster than normal.

However, this zeolite was only available in powder form, so we molded it in-house for use in water treatment and searched for molded products. As a result, we found bead-shaped active oxygen adsorption zeolite and decided to use column circulation treatment to ensure stable treatment.

Column circulation treatment of catalyst

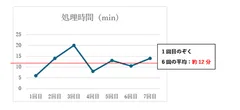

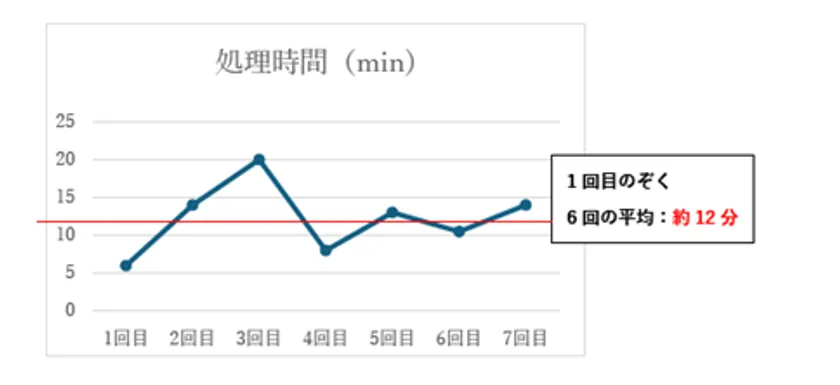

In order to prove that the decrease in rhodamine was not due to zeolite adsorption, we conducted seven consecutive treatments.

Confirmation of continuous treatment

As a result, it was confirmed that the ROS catalyst treatment was 10 times faster than the standard ROS treatment and nearly 20 times faster than the ozone treatment.

What the activated oxygen catalyst treatment can do

Easy decomposition of highly concentrated and persistent compounds in industrial wastewater → Reduction of industrial wastewater

Reduction of running cost of industrial wastewater

Reduction of the number of post-stage facilities (especially activated sludge treatment facilities) by pre-treatment at sewage treatment plants → Reduction of excess sludge generated

Decomposition treatment of persistent compounds before discharge → discharge of safe water, use of wastewater as a resource for recycling

Water treatment plants can treat emerging contaminants (CECs) that may be contained in source water.

Common to all water treatment facilities will be the reduction of energy consumption, reduction of sludge generated, possibility of reuse, etc.

Company Profile

Company name: WEF Technology Development Co.

Representative: Akira Aoyama, President

Location : 1-19-15 Do, Otsu-shi, Shiga

Establishment : July, 2016

Business description: Development and sales of water treatment, waste recycling, and Mg-related technologies

URL : https://aoyama-wefit.com

https://mgworld.aoyama-wefit.com/ (Magnesium World)

- Category:

- Corporate Trends