Alps Logistics Co., Ltd. has decided to adopt “rBox,” an automated warehouse specializing in small-sized products*1! Scheduled to exhibit at the 4th Smart Logistics EXPO (Tokyo Big Sight) to be held from January 22.

The system dispatches small boxes of electronic components and other items in order of order*2, realizing ultra-efficient storage*3 and rapid warehousing/unloading. RAX Solutions Corporation” finally started to cultivate customers outside of the optical lens industry in Japan.

RAX Solutions株式会社

RAX Solutions K.K. (Nihonbashi Chuo-ku, Tokyo, CEO Rupert Katritzky, “RAX”), a wholly owned subsidiary of RAX Group (Headquartered in Monaco, CEO Rupert Katritzky), announces that Alps Logistics Co. (Yokohama, Japan, CEO: Hideaki Terasaki, hereinafter referred to as “Alps Logistics”) has decided to adopt the automated warehouse “rBox” at its two locations in Kanagawa and Saitama prefectures in the fall of 2025.

Website] https://www.rax-solutions.com/jp-home/

Image of RAX Solutions rBox

While RAX has an established brand image in the optical lens industry, this is the first adoption of rBox by a customer in a different industry in Japan. We will continue to further explore areas that have not been matched by conventional automated systems and provide solutions that will please our customers.

In January, we will exhibit at the 4th Smart Logistics Expo at Tokyo Big Sight. We look forward to meeting many of our customers.

*1: Boxed items ranging in size from a business card box to a box the size of a shoebox, or items that fit into a dedicated box of the same size.

*2: Not in any order that is convenient for the system, but in the order in which the instructions are given.

*3: Depends on each case, but we have a track record of improving inventory efficiency by 300% or more.

■Product Description

This is a solution to automate the storage and delivery of a small quantity of high-mix, low-volume, small-sized products.

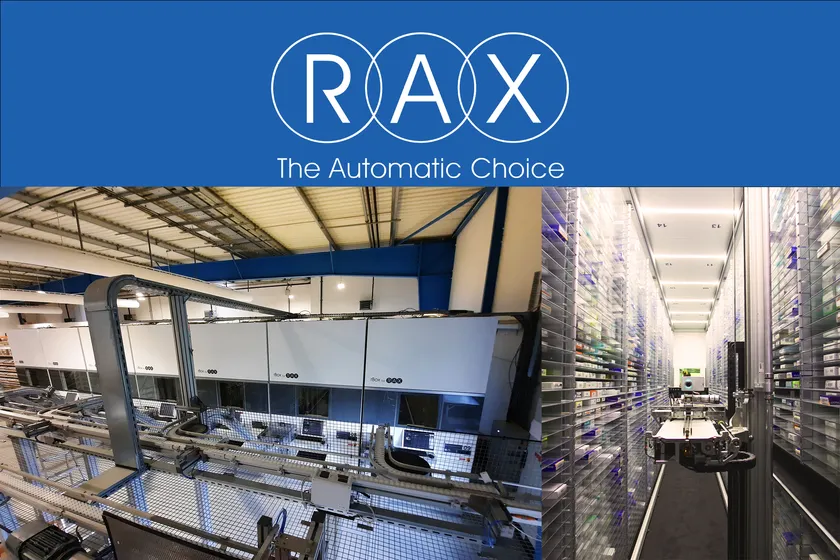

With our unique*4 “DISR (Direct Item Storage & Retrieval)”, “Order-To-Person” or “Order-To-Box” (otherwise known as “Single-Order Picking”), which means that all items in the order are picked and dispatched to the operator or directly to the shipping carton, unlike “Good-To-Person”, the conventional automation approach, which bins containing goods are delivered, and the person picks the goods from the bins for the number of times in the order.

The system is controlled by RAM, our core technology, and is linked to various systems to fully automate the end-to-end process, from receiving to shipping, and from picking to manufacturing and shipping, in accordance with customer needs and product types.

*4: This is the first technology of its kind outside of the medical industry in Japan. According to our research.

Examples of use:

e-commerce distribution center for small box products such as contact lenses and cosmetics.

Complete automation (unmanned) and control of a series of flows, including full automation of warehousing, forming shipping cartons, dispensing products into cartons, enclosing flyers, sealing cartons and attaching shipping slip labels, and sorting cartons by delivery company.

Eyeglass lens manufacturing base.

Automated warehousing of semi-finished and finished lenses, storage management, and dispensing of left and right lenses in pairs on a single job tray on a conveyor leading to the manufacturing process. In addition, automatic matching of lenses and frames after processing and coating, etc.

Research facilities and distribution centers that handle products as small as the palm of your hand.

Coordination from inventory management to shipping processes for laboratory materials, essential oils in small bottles, spare parts for vintage watches, electronic components, smartphones after refurbishing, etc. in dedicated boxes, trays and stands.

Illustration of the solution

■Key Factors in Choosing "rBox" (Comments by Yukinori Nodono, Senior Manager, Storage BU, Storage BU Division, ALPS Logistics Co.)

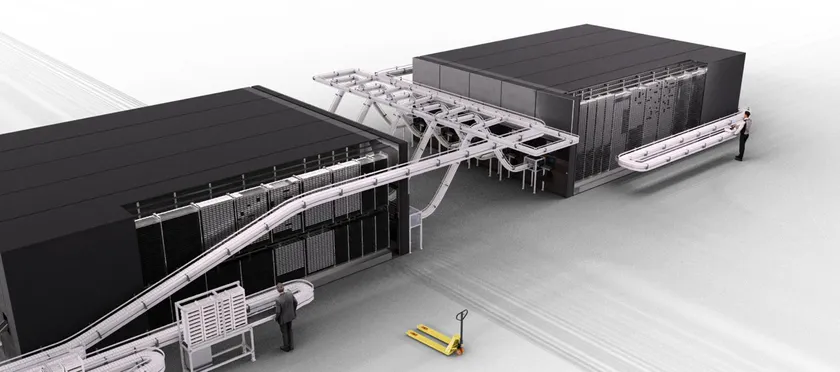

As the person in charge of selecting warehouse automation solutions for Alps Logistics, I have introduced many automation solutions in recent years. rBox" by RAX Solutions, The "rBox" of RAX Solutions was the only option that could achieve the ideal operation in terms of its ability to store items efficiently in "small box units," which no other company offers, and its ability to discharge items onto the conveyor in the order of the shipping instructions printed from the WMS. The "rBox" is also lightweight, with a required load capacity of 600-800 kg per square meter, and could be installed in our distribution warehouse. In addition to improving the efficiency of product storage and picking, we anticipate a significant improvement in storage efficiency, and are preparing to start operations in the fall of 2025.

Inside of rBox Shelf

■Activities in Japan (Comment by Taku Shimizu, Head of Sales and Business Development, RAX Solutions K.k.)

In my previous position, I was responsible for launching the domestic business of automatic drug box dispensing robots, which are a tributary of European dispensing pharmacies, and we received many requests from different industries to consider introducing the system. This was the same experience that our CEO had decades earlier in Europe. We will continue to provide solutions that contribute to business in a wide range of fields outside of the optical lens industry by making more people aware of our technology, software, and experience that has evolved for the industry.

■Event Information

We are pleased to announce that we will exhibit at the 4th Smart Logistics EXPO to be held at Tokyo Big Sight from January 22, 2025.

Dates : January 22 (Wed.) - 24 (Fri.), 2025

Venue :Tokyo Big Sight

Booth location: S17-40

Details and application:here (https://www.nepconjapan.jp/tokyo/ja-jp/register.html?code=1244275130353896-PYX)

■About Alps Logistics Co.

Location : 1756 Shinwa-cho, Kohoku-ku, Yokohama City, Kanagawa Prefecture

Representative Director : Hideaki Terasaki

Business Description :

Comprehensive logistics company providing integrated transportation, storage, import/export, and product sales of electronic components, etc.

- Transportation: Motor truck transportation business, freight forwarding handling business

- Storage: Warehousing and packing

- Import/export : Import/export cargo handling, customs clearance, air cargo transportation, air cargo transportation agency

- Others: Manufacturing and sales of packaging materials, manufacturing and sales of synthetic resin materials, sales of electronic devices, etc.

Home Page: https://www.alps-logistics.com/

■About RAX Group

Since 1993, in the process of becoming a European leader in installing logistics automation systems for hospitals and dispensaries, RAX recognized the demand for automation solutions for small goods outside of the medical industry and developed its own technology to meet the requirements of each industrial customer, establishing the RAX brand in 2015. RAX has over 10 years of experience and proven track record in providing automation solutions worldwide, specializing in the manufacturing, distribution, and storage management of eyeglasses and contacts in the optical lens industry. We listen to our customers and offer the best solutions, including full automation (without human intervention), and can plan for phased implementation if desired. For more information, please visit RAX-Solutions.com (https://www.rax-solutions.com/jp-home/).

- Category:

- Corporate Trends

- Genres:

- Technology General Business Economy(Japan)