Use of agricultural waste (rice husks) to suppress paddy methane generation, Rice husks can be used to prevent high temperatures in rice paddies

With the patented technology "Atmospheric Generated Active Oxygen" developed by WEF Technology, Success in Simultaneous Production of Biochar and Non-Crystalline Silica from Rice Husks at Low Cost and in a Short Time

WEF技術開発株式会社

WEF Technology Development Co. (Location: Otsu City, Shiga Prefecture; President: Akira Aoyama), which has the world's leading patented technology for generating active oxygen from oxygen in the air, has succeeded in simultaneously producing biochar and non-crystalline silica from rice husks at low cost and in a short time by using WEF's patented technology "atmospherically generated active oxygen". The company has succeeded in simultaneously producing biochar and amorphous silica from rice husks at low cost and in a short time.

Global warming has caused rice cultivation to face major problems. One is a perpetrator problem and the other is a victim problem.

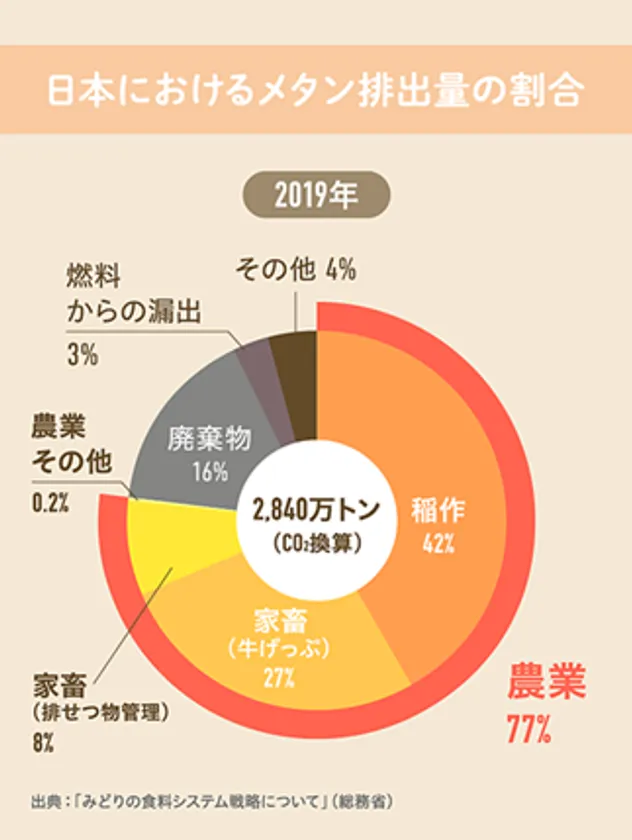

The perpetrator problem is that when rice paddies are flooded, the soil becomes anaerobic and methane bacteria are activated, resulting in the production of large amounts of methane. As shown in the figure below, rice cultivation is the number one source of methane in Japan. This makes agriculture a non-environmental industry, and reducing methane in rice cultivation is a major issue for all of Asia, where rice cultivation is thriving.

On the other hand, a victim problem is the various stresses on rice caused by global warming. Rice is susceptible to high temperatures, and stresses such as temperature (high temperatures), wind, sunshine hours, and insect pests are said to inevitably reduce yield and quality, even if the increase in CO2 is offset by the positive effects on rice growth.

Percentage of Methane Emissions in Japan

■ Effect of Biochar on Paddy Methane Generation

Here are two published papers.

・Biochar application to rice paddies was found to reduce methane emissions by 22.9%. In addition, biochar increased SOC (soil organic carbon) by 36.3% and crop yield by 16.2%. These results suggest that biochar can be an effective solution to mitigate greenhouse gas emissions and increase SOC content and crop yield in this region.

(Effects of Biochar on Methane Emissions and Crop Yields in East Asian Paddy Fields: A Regional Scale Meta-Analysis.)

The results showed that commercially available rice husk charcoal can be expected to suppress methane emissions throughout the rice cultivation period, regardless of water management. The results of this experiment also showed that a minimum mixing rate of 250 kg/10a of rice husk charcoal is sufficient to suppress methane, and that increasing the mixing rate will further increase the suppression effect.

(Scientific Verification of Paddy Rice Farming Method Using Biochar: Faculty of Environmental Science, University of Shiga Prefecture)

General effects of biochar

It reduces soil acidity, increases buffering capacity, increases dissolved and total organic C, CEC, available nutrients, water retention, and clumping stability, reduces bulk density, increases microbial activity, promotes nutrient cycling, and reduces nitrogen leaching and volatilization.

Biochar increases P (phosphorus) availability by an average of 4.6x, reduces plant tissue concentrations of heavy metals by 17% to 39%, increases SOC by 3.8% (range -21% to +20%) through negative priming, and reduces non-CO2 GHG emissions from soil by 12% to 50%.

Biochar combined with minerals, organic fertilizers, and minerals is the most cost-effective formulation because of its high nutrient use efficiency.

■Use of silica as a countermeasure against high temperatures in rice

■Silica can counter various types of aviotic stresses, including physical (drought, lodging, low and high temperatures, UV light) and chemical (heavy metals, salinity) stresses.

(Ma et al., 2006; Liang et al., 2007; Li et al., 2008)

General effects of silica

■Increased photosynthesis and yield

Increased resistance to disease

Increased resistance to pests

Increased resistance to drought and salinity

Increases resistance to flooding

Improved nutrient balance

■Improve resistance to ultraviolet radiation

Increased resistance to high and low temperatures

■Increase carbon sequestration

■Inhibit uptake of heavy metals

Biochar and silica are the solution to Asia's rice problem.

Rice accumulates about 10% of its above-ground dry weight in silicon. Of this, a little less than 80% is organic matter such as cellulose, and the remaining 20%-plus inorganic matter consists mostly of amorphous silica and a few minerals.

In Japan, about 2 million tons of rice husks are discharged every year, of which 670,000 tons are discarded. If we can utilize this rice husk, agricultural waste (rice husk) can solve both global warming and food problems.

WEF technology developed to decompose organic matter by active oxygen + reaction heat, leaving inorganic matter

Activated oxygen decomposes the atomic bonds of nearly 80% of the cellulose in the rice husk, ultimately reducing it to only inorganic silica, which is left as biochar by stopping the process early.

Rice husk before treatment

Rice husks

Finished biochar silica

Removal of biochar silica

Activated Oxygen Organic Matter Decomposition Equipment "Polaris 3.0

<Features of activated oxygen treatment

1) Low-cost treatment: Energy consumption during treatment is limited to the activated oxygen input fans (50W x 2 units).

2) Short treatment time: treatment time is around 3 hours

3) Low temperature treatment: Treatment temperature is 250-300℃, which enables complete amorphization.

4) Use of rice husks during the off-season: When husks are not treated, they can be used for decomposition of agricultural waste (weed prevention, heat shield sheets, etc.).

Rice husk biochar-silica" will create a new form of rice cultivation in the future.

Effects of rice husk biochar silica rice cultivation

1) The two effects of rice rice husk biochar silica rice cultivation, suppression of paddy field methane generation and buried charcoal, can be aggregated and a large amount of CO2 sales can be expected through "carbon pricing".

2) Rice cultivation that can overcome the stress of climate change will ensure (increase) yield and quality.

3) Reduction of phosphorus fertilizer use (value-added use of charcoal)

4) Reduction of rice waste.

Company Profile

Company name: WEF Technology Development Co.

Representative: Akira Aoyama, President

Location: 1-19-15 Do, Otsu-shi, Shiga

Establishment : July 2016

Business description: Development and sales of water treatment, waste recycling, and Mg-related technologies

URL : https://aoyama-wefit.com

- Category:

- Technology & Development