Subscribers to Collaborative Robots Are Revitalizing Japan's International Competitiveness Interview with Wing Robotics, Inc. published on May 30

Collaborative robots to factories of small and medium-sized companies with serious labor shortages Venture companies that provide cooperative robots to small and medium-sized factories

東京都企業立地相談センター

The Tokyo Metropolitan Government's Consultation Center for New Business Location conducted an interview with Mr. Liping Feng, President of Wing Robotics Corporation (Location: Koto-ku, Tokyo), which was published on the Tokyo Metropolitan Government's Consultation Center for New Business Location website on Thursday, May 30, 2024.

Wing Robotics Corporation President and Representative Director Liping Feng

■Renewing Japan's International Competitiveness with High-Performance Cooperative Robot "SUBSUKU

As you know, robots are playing an increasingly active role in everything from work in manufacturing and food factories to serving wagons in restaurants. Such industrial robots can be divided into two categories: "industrial robots," which perform the heavy and dangerous work that was once performed by humans, and "cooperative robots," which work side-by-side with humans to improve production efficiency.

The latter type, cooperative robots, are said to be the "trump card" in the fight against Japan's growing labor shortage, and are expected to grow. Wing Robotics is a venture company that has made its presence felt with its unique approach of providing cooperative robots to small and medium-sized factories, where labor shortages are particularly serious. We interviewed Mr. Liping Feng, President and Representative Director, about the company's business, the prospects for cooperative robots, and the advantages of its location.

Japan has an environment where the characteristics of collaborative robots can be utilized.

Mr. Feng started Wing Robotics Corporation in September 2018. After a period of preparation, he launched a robot subscription service in April 2021. Prior to that, he worked for about 20 years as a consultant for Japanese manufacturers to help them expand into China and other parts of Asia.

I received high evaluations from numerous clients, but at the same time, I had to put my consulting business on hold because I was spending less and less time with my family in Japan. After that, I decided to take advantage of the high level of Japanese technology that I had realized through my consulting business as a business that I could continue to operate from my base in Tokyo.

Mr. Feng's focus was on small and medium-sized companies that were in serious crisis.

About 52% of them were facing downsizing, bankruptcy, M&A, or other business restructuring, and the main reason behind this was a shortage of labor (according to a survey by the Jonan Shinkin Bank). The three main reasons for the shortage were "falling birthrate and aging population," "imbalance between supply and demand," and "delay in introduction of DX and robots. When I was a consultant, I was involved in a project for a telecommunications equipment manufacturer involving a factory that manufactures 150 million smartphones annually, and I had a wealth of knowledge.

Mr. Feng then set his sights on developing applications for "collaborative robots. The global market for collaborative robots is expected to grow from US$1.3 billion in 2021 to US$40.16 billion (approximately 6.5 trillion yen) in 2030 (Note: according to a Panorama Data Insights survey), making it an extremely attractive market.

In Japan, there is an environment in which the characteristics of cooperative robots can be easily utilized. For example, cooperative robots can easily change models and flexibly respond to the fact that there are many factories that produce a wide variety of products in small quantities, they are compact and easy to install in many factories where space is limited, and they can be easily handled by non-specialists in response to the aging population and shortage of IT personnel. The advantages of cooperative robots make them suitable for a wide range of applications.

However, there are some challenges to introducing these robots.

First of all, because the operating methods differ depending on the manufacturer of the cooperative robots, the robot technicians (SIer: System Integrator) who operate the robots must learn how to operate them according to the manufacturer. Furthermore, there are only about 10,000 to 20,000 robot engineers in Japan, which is only about 0.0002% of the Japanese population, which is a major barrier. We have been working to develop applications for cooperative robots in order to clear up these issues.

We estimate that the cooperative robot market in Japan is worth approximately 400 billion yen," said Feng.

Data Accumulation Facilitates Technology Transfer and Generational Change

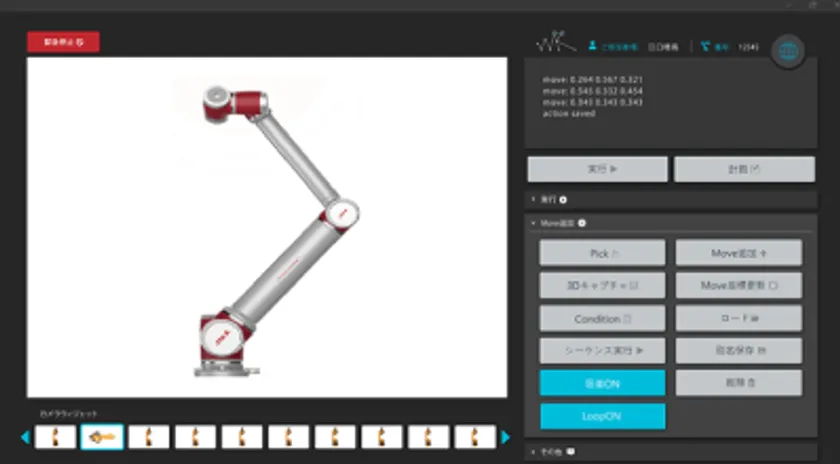

The application developed by Wing Robotics is WING-Bot, a remote control system for cooperative robots. WING-Bot allows SIers to operate and monitor cooperative robots from a remote location, eliminating the need for a dedicated manager at the manufacturing site where the robots are installed.

WING-Bot is compatible with "ROS: Robot Operating System," an open source software for robot development developed by Willow Garage in the U.S. Since many cooperative robots are compatible with ROS, it is easy for different manufacturers to operate and manage the system. This is one of the strengths of the WING-Bot. In addition, from the viewpoint of cost reduction, the camera, which is the key to remote operation, can be replaced by a commercially available smartphone. By checking the images captured by the smartphone's camera, the robot can be controlled from a remote location and instructions can be given to on-site staff as needed.

Operation screen of the WING-Bot remote control system

The WING-Bot is especially effective when a "chocolate stoppage" occurs.

To ensure the safety of people working side by side, the cooperating robots are equipped with a function to stop immediately if they come into contact with each other, even slightly, or if some abnormality occurs. This is called a "choco stop. Each time this happens, the production line stops, but our engineers can immediately restore the line from a remote location, so the downtime is minimal and labor productivity is not compromised.

However, despite its superiority, the cost of the system is a bottleneck in its implementation. That is why the company offers the "Robot Subscription Service.

The current alpha version is relatively low-cost, starting at approximately 100,000 yen per unit on a monthly basis, and can be installed in as little as one day, without slowing down on-site work. Our staff will handle the necessary parts setup and programming at the time of installation, as well as any problems that may arise after installation. Another feature of the next beta version is that it is equipped with a camera and AI, so it can automatically plan when it runs out of parts to grab, or calculate the shortest route to complete the job.

The robot's work history can also be stored as data and accurately reproduced. Therefore, if cooperative robots can be introduced, it is unlikely that work will be delayed after the retirement of veteran craftsmen, and there are high expectations for the smooth transfer of skills and generational change.

The camera, which is the key to remote control, can be replaced by a smartphone. Since cooperative robots can learn many complex movements, they can be moved around the factory to support different types of work by replacing parts and programs.

Advantages of Locating in Koto and Tokyo: A Diverse Environment to Support Robotics Companies

Finally, we asked about the product development support laboratory in the Tokyo Metropolitan Industrial Technology Research Institute (TIRI) in Koto-ku, where the company has its development base, and the appeal of the surrounding environment.

The company is very satisfied with the environment within the TMITRI.

There are so many advantages. First of all, the elevators are large, which is a great benefit for robotics companies because it is easy to carry robots out of the building. Also, the presence of a 5G base station in the adjacent Telecom Center is essential for our robot remote control. In addition, the free use of many machines in the prototype processing room, including 3D printers, lathes, drilling machines, and automatic polishers, is also an attractive feature.

In addition, he points out that there are many other attractions besides the hardware.

In addition to the advantages of 24-hour access and the ability to continue working as long as one likes, opportunities to exhibit at exhibitions, and various types of advice from a variety of mentors, "partnerships" with other tenants in the same lab are also unique to this facility. In addition, the "partnerships" with other companies in the same lab are also unique to this center, as there are many AI and robotics companies working in the same field, so the information shared with each other is very meaningful. I remember thinking, "I remember you know a lot about that area...! It is not uncommon for me to visit them directly and learn from them. Of course, it's a win-win situation, so when other companies come to interview us, we do our best to cooperate with them.

In addition, the company also benefits greatly from its "Tokyo location," which offers various subsidies and many opportunities to participate in contests. Taking advantage of this favorable environment in terms of both hardware and software, Mr. Feng is looking to the future to take his business to the next level.

Unfortunately, Japan's labor productivity is currently one of the lowest in the developed world. We want to introduce and spread collaborative robots to the manufacturing sites of small and medium-sized companies that support the Japanese economy, and thereby improve the country's international competitiveness.

In the past, cooperative robots and art have been fused together, with TV Asahi engineers using the open-source 3DCG software Blender to create the motion of a robot arm at "GoTech 2022" (hosted by TV Asahi) in March 2022. The artwork was completed with technical support from Wing Robotics, Inc. The project showed the possibility of expanding opportunities for many companies and people, including creators who use "Blender," to utilize robots.

■Company Profile

Company Name : Wing Robotics, Inc.

Location : 2-4-10 Aomi, Koto-ku, Tokyo

Tokyo Metropolitan Industrial Technology Research Institute

Room 306, Product Development Support Laboratory, Tokyo Metropolitan Industrial Technology Research Institute

Representative : Representative Director and President, Li-Ping Feng

Establishment : September, 2018

Start of business : April 2021

Business : Providing subscription services for next-generation collaborative robots

Website : https://wing-robotics.com/

Source of information

Tokyo Metropolitan Enterprise Location Consultation Center

Website: https://ilsc.tokyo/

What is the Tokyo Metropolitan Consultation Center for New Business Location?

The Tokyo Metropolitan Corporate Location Advisory Center provides free consultation for companies and sole proprietors in search of a "location" to establish or expand their business. We will ask you about your desired conditions and make a simultaneous inquiry to private real estate businesses that handle offices, stores, factories, and business sites.

We also provide information on public property information and support systems of the Tokyo Metropolitan Government and municipalities in Tokyo.

(The Tokyo Metropolitan Government's Consultation Center for New Business Location is operated by the Bureau of Industrial and Labor Affairs, Tokyo Metropolitan Government.)

Articles

Interviews with companies that have located and are active in Tokyo and persons in charge of corporate support from the Tokyo Metropolitan Government and its municipalities are posted on the website of the Tokyo Metropolitan Government's Consultation Center for Investors in Business Location.

- Category:

- Corporate Trends

- Genres:

- General Business Economy(Japan) Technology