Green Science Alliance Makes from Black Mass, a Recycled Material Environmentally Sustainable and Sustainable Cathode Material for Lithium-Ion Batteries

Environmentally friendly and sustainable battery materials from raw materials to manufacturing processes

GSアライアンス株式会社

Green Science Alliance Corporation (Headquarters: Kawanishi City, Hyogo Prefecture, President: Dr. Ryohei Mori (Engineering)) has developed an environmentally friendly and sustainable cathode material based on black mass, a recycled material extracted from discarded and recovered lithium-ion batteries.

Cathode material synthesized from black mass

■ Key Points

1. black mass is a recycled material extracted from lithium-ion batteries, which looks like black powder and contains a large amount of rare metals such as cobalt, nickel, manganese, and lithium.

2. The production of rare metals such as cobalt and nickel, which are necessary for lithium-ion batteries, is unevenly distributed in certain regions such as Russia, China, Africa, and South America, and there is always a risk of political supply instability and price fluctuation. Therefore, it is important to recycle these metal resources.

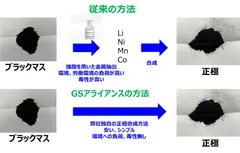

3. Currently, studies are being conducted to extract metals such as cobalt and nickel from black mass using sulfuric acid, hydrochloric acid, and other hazardous chemicals to make cathodes for lithium-ion batteries again, but this process is dangerous to workers, burdensome to machinery and equipment, and the environment, and is expensive.

4. we have synthesized a cathode from black mass using our own simple process without using any such hazardous chemicals. 5.

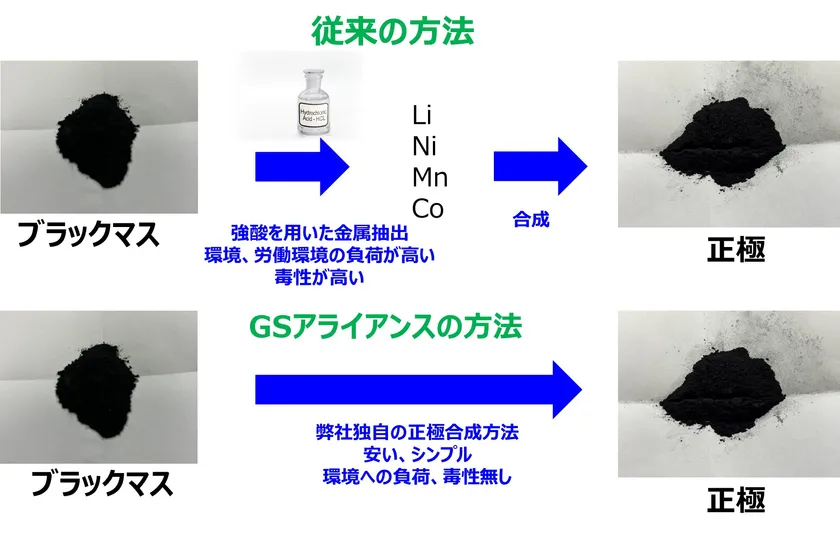

5. lithium-ion batteries using the blackmass-derived cathode synthesized by our unique process showed 85-90% initial capacity compared to commercially available NMC111, and were relatively stable after 100 cycles, just like NMC111.

6. The simplicity of the process, without using any hazardous chemicals, makes it an environmentally friendly and sustainable cathode material for lithium-ion batteries.

In today's society, lithium-ion batteries are a typical storage battery, and are used in a variety of storage batteries including electric vehicles, smartphones, and personal computers. However, in order to meet future demands for more efficient electric vehicles and a smart grid society, there is a need to further improve battery capacity and develop inexpensive lithium-ion batteries.

GS Alliance, Inc. is actively engaged in research and development of various next-generation rechargeable batteries, including lithium-sulfur batteries, aluminum-based rechargeable batteries, excess lithium cathodes, oxide-based solid electrolytes, and electrode materials based on metal-organic structures, We synthesize and adjust electrodes, electrolytes, and separators, the constituent materials of which greatly affect battery performance, entirely in-house. In addition, we are also making inks for electrode application, creating test cells, conducting electrochemical measurements, analysis, and preparing for small-volume pilot production, all in house.

Under these circumstances, Dr. Ryohei Mori (engineering) and Researcher Katsuhito Furunishi have developed an environmentally friendly and sustainable cathode material synthesized from black mass, a recycled material extracted from discarded and recovered lithium-ion batteries.

Black mass is a recycled material taken from lithium-ion batteries, which is a black powder and contains rare metals such as cobalt, nickel, manganese, and lithium. Normally, metals such as cobalt, nickel, manganese, and lithium are extracted from black mass using strong acids and alkalis such as sulfuric acid, hydrochloric acid, and caustic soda, and these metals are solidified by precipitation reaction and synthesized as cathode materials again in many cases, but this method uses strong acids, This method, however, uses strong acids, etc., which are environmentally hazardous, toxic, harmful to the working environment, and expensive. In contrast, we have succeeded in synthesizing new cathode materials from blackmass using a simple, inexpensive, and environmentally friendly method that does not use strong acids or other highly toxic chemicals.

Compared to a commercially available cathode material called NMC111 (LiNi0.33Mn0.33Co0.33O2), the lithium-ion battery using the blackmass-derived cathode synthesized by our unique method showed 85-90% initial capacity and, like NMC111, was relatively It was stable. The blurring of elemental content of the included metals such as Li, Mn, and Co, which is a drawback of recycled materials, was also adjusted and optimized as much as possible so that stable battery capacity and cycle characteristics could be achieved.

Thus, this blackmass-derived cathode material is an environmentally friendly and sustainable cathode material for lithium-ion batteries, since it is made from recycled materials and the synthesis method is non-toxic and inexpensive.

These results will be presented at the Fall Meeting of the American Chemical Society in Denver, Colorado, USA, this August.

GS Alliance plans to propose and sample the black mass-derived cathode prepared in this way to interested customers in Japan and overseas.

Comparison with conventional methods

Conceptual diagram of synthesis and re-creation of lithium-ion batteries

What is ■Black Mass?

In the main method of recycling lithium-ion batteries currently under consideration, used lithium-ion batteries are first collected, disassembled, and pulverized to remove major base metals (metals with large reserves and production volumes that are relatively easy to refine and recover) and other impurities. After these processes, a substance called "black mass," which is an apparent black powder, is extracted. This black mass contains the plastics, resins, electrolyte, binders, aluminum, copper, iron, steel, graphite, etc. that made up the lithium-ion battery. On the other hand, it also contains large amounts of valuable metals such as cobalt, nickel, manganese, and lithium, as mentioned above. Therefore, these valuable metals are extracted and used to regenerate new lithium-ion batteries. However, highly toxic chemicals such as sulfuric acid and hydrochloric acid are used in the process of extracting these metals, and there are concerns about the high environmental impact and toxicity of these chemicals on the plant, machinery, workers, and the environment in general.

Company name: GS Alliance Corporation (Fuji Pigment Co., Ltd. Group)

Representative: Dr. Ryohei Mori, President (Engineering)

Head office: 2-22-11 Kohana, Kawanishi, Hyogo, 666-0015, Japan

Business: Carbon neutral, decarbonization, and SDGs issues

Research and development of cutting-edge technologies in the environmental and energy fields

(Adopted by UNOPS GIC KOBE, a UN start-up company support program

adopted by UNOPS GIC KOBE, a UN start-up company support program, in 2020)

- Category:

- Technology & Development