Tatsumi Kogyo, a manufacturer, assembler, and installer of commercial prefabricated refrigerators, will Shipped its "first shipment" to a large frozen refrigerated distribution warehouse on March 8, 2024

While 57% of the respondents are considering new or expanded logistics facility relay bases, Many inquiries to Tatumi Kogyo from large frozen/refrigerated distribution warehouses

たつみ工業株式会社

Tatsumi Kogyo Corporation, an insulation panel manufacturer with approximately 80% share in walk-in refrigerators for convenience stores in the Tokyo metropolitan area and almost 100% share in 7-Eleven stores in Tokyo, Kanagawa, Chiba, and other metropolitan areas, has developed manufacturing, assembly, and installation of prefabricated refrigerators for commercial use, and will ship its "first shipment" from its new Kisarazu Plant on The "first shipment" was made on March 8, 2024. The delivery will be to a large-scale distribution center under construction in Noda City, Chiba Prefecture, where the panels will be installed as insulation panel walls for a dedicated frozen/refrigerated area under construction in one corner of the floor.

Tatsumi Kogyo is constructing a plant and office building on a 43,377-square-meter site in Kisarazu, Chiba Prefecture, and is expanding its business into large freezers and refrigerators, distribution centers, and clean rooms, in addition to conventional panels for prefabricated refrigerators for commercial use in convenience stores and supermarkets. Since last fall, Tatsumi Kogyo has been receiving a great number of inquiries from large logistics warehouses located at logistics relay points.

First shipment

The shortage of frozen/refrigerated warehouses: 30% of them are over 40 years old.

Recently, there is a growing concern among logistics professionals in Japan that there will be a shortage of frozen and refrigerated warehouses for storing agricultural and livestock products, marine products, and frozen foods in the future.

According to an estimate of the required supply of refrigerated warehouses by the Japan Economic Research Institute, storage demand will remain flat from the current level until around 2030, and based on the assumption that half of the refrigerated warehouses built in the 1950s will be disposed of, new investment of 300,000 tons per year will be required over the next 10 years.

CBRE is also considering the construction of new relay bases in response to the 2024 problem.

According to the "Tenant Survey 2023 on the Use of Logistics Facilities," a special report released by CBRE, 57% of respondents answered that they will "expand" the total area of their warehouses over the next three years, indicating that their plans for logistics bases are still strong, following the 59% response in 2022.

The frozen food market, which continues to expand, will reach a record high level in 2022.

The frozen food market continues to expand due to the increase in the number of dual-earner households and elderly households, as well as the impact of the increased demand for simplified food due to the voluntary restraint on going out due to the spread of the new coronavirus infection. The value (factory shipments) was 763.9 billion yen, up 4.0%, a record high for the third consecutive year. Source: Japan Frozen Foods Association, domestic production of frozen foods from January to December 2022.

About Kisarazu Plant

Front view of Tatumi Kisarazu Plant

View of the plant from the sky

The world's first formulation of continuous noncombustible polyurethane heat insulation panels (HFO PIR), the thickest in Japan at 300mm.

TATUMI PANEL

1. urethane made by BASF of Germany

The world's first noncombustible panel formulation, made by BASF of Germany, is used. The ability to form a high quality core material with minimal molding defects and smooth, non-peeling surface makes it possible to manufacture heat insulation panels for large refrigerator-freezers with thicknesses of 150mm to 250mm, depending on the location and purpose of use. Potentially, it can also produce Japan's thickest heat-insulating panels of 300 mm.

2. continuous line production system

In anticipation of a shortage of factory workers in the next 10-15 years, the factory is equipped with facilities and processes that enable production of high-quality products with only a few operators. By installing a continuous production line from Hennecke-OMS of Germany, productivity is dramatically improved compared to the conventional batch system. Shortened lead time and mass production became possible.

3. packaging method that contributes to waste reduction

In addition to automatic packing, EPS materials are used instead of conventional wooden pallets. This is a new environmentally friendly packing method that contributes to the reduction of waste materials on site.

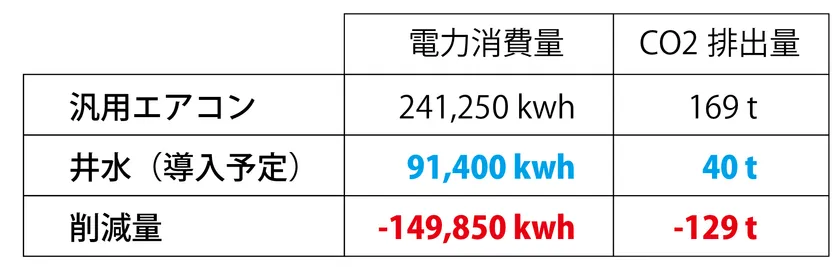

The heat exchange system uses a water-cooling system instead of air-cooling, which significantly reduces electricity consumption and CO2 emissions.

Amount of reduction

The use of a water-cooling system instead of air-cooling for the cooling system of production facilities prevents heat island effects by reducing exhaust heat from air conditioning and temperature control equipment and through heat recycling efforts. In addition, the new system reduces electricity consumption by up to 62% and CO2 emissions by up to 76%, contributing to the SDGs.

The "3K" image of conventional factories has been dispelled.

The new building is designed to be comfortable and pleasant to work in and take breaks in, and to provide a good work environment.

Open space for employees

About Tatsumi Industry Co.

<Tatsumi Kogyo has been manufacturing prefabricated refrigerators for business use for 62 years and covers almost 100% of 7-Eleven stores in the Tokyo metropolitan area.

Tatsumi Kogyo Corporation, headquartered in Kawasaki City, Kanagawa Prefecture, has been a specialized manufacturer of prefabricated commercial refrigerators since its establishment in 1962. Commercial refrigerators typically handle food products, but the company also handles a variety of custom orders, including refrigerators for flower arrangement stores, wine cellars, and aquarium feeders. In particular, for walk-in refrigerators for convenience stores, we cover almost 100% of 7-Eleven stores in Tokyo, Kanagawa, Chiba, and other metropolitan areas. We also cover about 80% of the major convenience store chains, including Lawson, FamilyMart, Ministop, New Days, and others.

Record number of deaths per year in "multi-fatality society"; orders for refrigerators for mortuary use five times as many as in the past.

With the aging of the population, the new Corona has triggered a change in funeral styles, with a decrease in "general funerals" and an increase in "direct funerals and cremation ceremonies. As a result, people are forced to lay in state for longer periods of time at crematoriums, and the waiting period for cremation is longer than ever before, leading to a sharp increase in inquiries for our "refrigerators for resting the dead. We have received requests from many funeral service companies and police departments, etc., for our prefabricated refrigerators, which can respond to various on-site situations based on our many years of expertise in the manufacture of prefabricated refrigerators for business use.

Future Prospects

In addition to the business for convenience stores, which has already become a lifeline, we expect to continue to expand business at the Kawasaki Plant, including new business such as refrigerators for mortuary use, utilizing the technological capabilities we have cultivated over our 62 years in business. The Kisarazu Plant, on the other hand, is the only plant in Japan capable of producing urethane heat insulation panels of 200 mm or more, and is aiming for sales of 1 billion yen in the first year and 2 billion yen or more in the next and subsequent years, with the aim of being used in distribution centers, large refrigerated freezer warehouses, semiconductor clean room factories, etc., where demand is strong. In the future, the company will also develop sales with an eye to data center cooling, which consumes large amounts of electricity, and large refrigerated warehouses for medical applications.

Company Profile

Company name: Tatumi Industries Co.

Location: Head Office

4-1-13 Ogura, Saiwai-ku, Kawasaki-shi, Kanagawa, 212-0054, Japan

<Kisarazu Plant

2-8-1, Kazusa-Kamashi, Kisarazu-shi, Chiba 292-0818, Japan

Representative Director: Hiroyuki Iwane

Establishment: April 1962

Capital : 70 million yen

URL : https://tatumikougyou.co.jp/

Business Description: Design, manufacture, assembly, and installation of prefabricated refrigerators for commercial use,

Prefabricated refrigerator-freezers, commercial refrigerators, clean rooms,

shielded rooms, soundproof rooms, and complete air-conditioning and heating works

Major customers: (in no particular order, titles omitted)

Seven-Eleven Japan, Lawson, FamilyMart,

Starbucks Coffee, The Westin Tokyo,

Asahi Breweries, Bunmeido, NHK Broadcasting Technology Research Laboratories, U.S. Army Base,

National Hospital Organization Yokohama Medical Center,

Sony Computer Science Laboratories,

Sanrio Puroland, etc.

- Category:

- Corporate Trends

- Genres:

- General Business Economy(Japan) Technology