Announced "Kensa Tech HandFoot" for universal design.

株式会社プロスパー クリエイティブ

Prosper Creative Inc. (Head Office: Chuo-ku, Tokyo; Representative Director: Hideki Kawabata), which developed Japan's first off-line print inspection equipment system and sells it mainly to the printing and packaging industries, as well as to a wide range of companies that order printed materials, including pharmaceutical, cosmetic, and insurance companies, announces the release of its universal design "Kensa Tech HandFoot We are pleased to announce the release of "Kensa Tech HandFoot.

The product is scheduled to go on sale in April.

Outline of the device system

The "Kensa Tech HandFoot" uses a web camera and foot pedal switch to provide inspection instructions.

High-precision multiple threshold inspection (our patented technology), which used to require complicated operations, is now instantly realized with simple operations. High-precision inspection operations with inspector-friendly operability are now possible, even for slight printing flaws or stains that are difficult to detect even by visual inspection.

In addition, the system enables users to select the most appropriate instruction method from multiple inspection instruction methods, not just keyboard and mouse, making it easy for anyone to find abnormalities in a short period of time.

Basic system and inspection screen

Previous issues and solutions

Conventionally, printed matter inspections are performed by setting inspection thresholds (reference values) and using a keyboard or mouse to give inspection instructions.

Here are the issues and solutions.

Issue 1.

Printed matter inspection uses image data of prints and printed matter to be compared that is input by a scanner or camera, but it is difficult to detect dirt or flaws in printed matter that are so slight that they cannot be seen, However, it takes time to set the optimum value.

It takes about 5 seconds or more for each threshold change instruction to find the optimum threshold value. For example, it takes three times as long just to switch three levels, which is a very time-consuming task for printed materials with many pages.

Solution:

To solve this problem, we have newly developed "Multiple Threshold Switching Inspection Software," which stores multiple images for each threshold of the desired inspection image density in memory and allows "instant" switching and confirmation of the threshold value, thereby enabling stress-free, high-precision inspection at the appropriate threshold value. This software enables stress-free, high-precision inspections at the appropriate thresholds.

Issue 2.

A printing company that had installed our off-line inspection system asked us if we could make the buttons for inputting instructions larger, since they are also used by physically handicapped persons. Until now, there was no inspection system that could be used by people with disabilities to perform inspections with high accuracy and convenience.

Solution:

This time, we developed "Multi-operation Inspection Instruction Software" that can be operated by hand using a web camera and by foot using a pedal, and added and enhanced inspection operation functions so that highly accurate inspections can be performed easily.

We are considering the use of hand operation only, foot pedal only, or a mix of hand and foot operation.

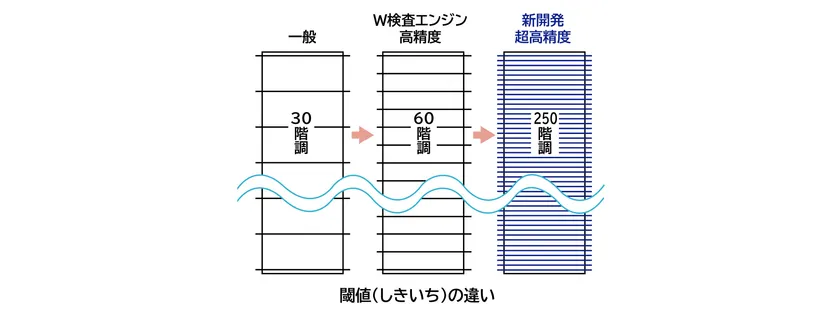

Newly developed multiple threshold switching inspection

The newly developed 250-step threshold switching setting that enables even finer inspection than the 60-step setting of our high-precision models equipped with the W inspection engine, and the technology that allows instantaneous image switching with the foot switch has made it possible to set the appropriate thresholds on the inspection equipment.

Image of conventional thresholds and newly developed thresholds

Aiming for Universal Design

In response to user requests, we have added an inspection function that uses a web camera to provide manual inspection instructions and a foot pedal triple foot switch to switch threshold images, enabling multi-operation inspection instructions and making it possible for those with inspection disabilities to use the system.

Web camera and foot pedal switch

[Prototype announced

The prototype of "Kensa Tech HandFoot," a high-precision printed matter inspection system that can be easily used by anyone, has been introduced to printing companies, publishers, editors, and companies that place printing orders, and has received operational evaluations, leading to sales specifications.

Kensa Tech HandFoot" will be on display at our exhibit at page2026 (Ikebukuro Sunshine City, Cultural Hall) starting February 18, where we will demonstrate the prototype printing equipment system and use the opportunity to confirm the response from visitors.

After that, we will exhibit and propose the system at our Ginza showroom not only to the general printing industry, but also to those involved in insurance, books, and various types of packaging that require off-line image inspection.

[To equipment that meets the needs of society

Prosper Creative Inc. aims for "Kensa Tech HandFoot" to be increasingly introduced as a device that promotes social advancement through employment by enabling high-precision inspections while utilizing a multi-operation inspection instruction function, even if the inspection operation is impaired. To this end, we will also conduct a survey of printing companies and companies that place printing orders regarding the use of "Kensa Tech HandFoot.

In the future, we plan to consider developing "Kensa Tech HandFoot" for other industries that require the multi-operation instruction technology of "Kensa Tech HandFoot".

Companies interested in distributing this product are invited to contact us. We are considering sales agents in the United States, Europe, and China.

Company Profile

Company name: Prosper Creative Inc.

Business Description: Developed and sold Japan's first off-line print quality control system.

In the field of comparative difference evaluation of images, we are developing color difference evaluation and defect inspection systems for printed materials.

We are developing defect inspection systems in the field of comparative difference evaluation of images.

It is the only technology in the world that can numerically measure colors and evaluate colors using images of printed materials input from a scanner.

This technology is the only one of its kind in the world.

This technology is used by many printing companies.

- Category:

- Services