WEF Technology Development succeeds in decomposing ammonia in the air with active oxygen.

Complete oxidative decomposition treatment of VOCs in air and ammonia-form nitrogen in water is also under verification.

WEF技術開発株式会社

WEF Technology Development Corporation has successfully decomposed ammonia in air using its proprietary active oxygen generation technology. This technology enables low-cost and simple treatment compared to conventional adsorption and ozone treatment.

■Reactive Oxygen Utilization and Global Issues

Until now, reactive oxygen species (hydroxyl radicals, superoxide, etc.) have been known to have extremely high oxidation capacity, but their extremely short lifespan has long made it difficult to generate large quantities of them and to apply them practically.

Conventional methods such as plasma, photocatalytic, and electrolytic methods have low generation efficiency of reactive oxygen species, and stable supply and reaction control are difficult.

In particular, the concept of decomposing solid organic matter with reactive oxygen species is almost unprecedented in the world.

The reason for this is that there was no technology to generate the necessary amount of reactive oxygen species at the reaction site.

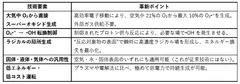

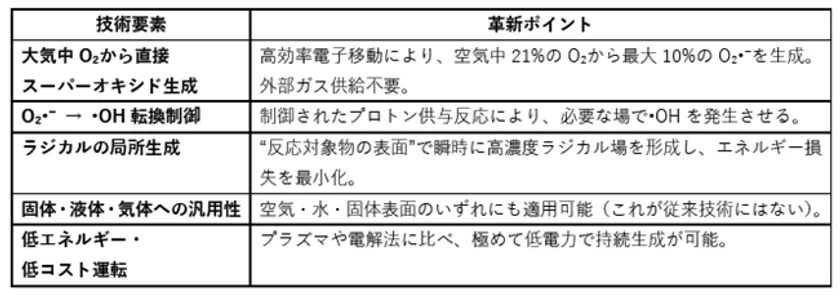

WEF Reactive Oxygen Species Utilization (Innovative Point of AOS Technology: Uniqueness of Technology)

Image (4)WEF active oxygen utilization

Reaction mechanism (schematic)

(1)AOS generates a large amount of O2- in the air → Blowing air into the reaction layer.

(2) At the water film (H+ supply) on the surface of the reaction layer: O2・- + H+ → HO2・- → HO2・- → HO2・- → HO2・- → HO2・- → HO2・- → HO2・- → OH

HO2- → ・・OH etc. (chain-like ・・OH formation)

(3) High concentration of ・・OH is locally generated and retained on the catalyst surface.

(4) ・・OH (adsorbed state) + NH3(g) → NH2・ → NOx intermediate by a series of oxidations

(5) OH(g) + NH3(g) → NH2 → NOx intermediate by a series of oxidations → Converted to N2 (denitrification-like reaction) or NOx is treated downstream under appropriate conditions.

OH is highly reactive and has a short lifetime, so the key is to "generate it upon contact with ammonia + catalyst retention.

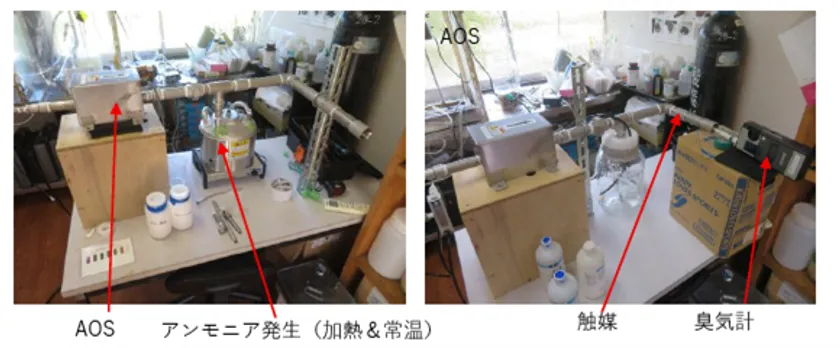

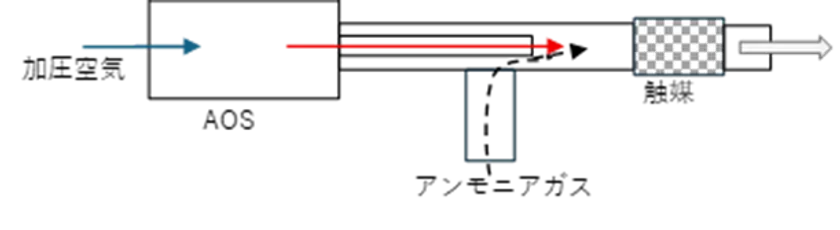

■Test Description

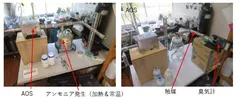

Image (1) Test photograph

Image (2) Explanation of the test

A liquid material that generates a large amount of ammonia when it boils was placed in a pressure vessel and heated by a heater (the other was generated at room temperature). When ammonia was generated, the gas was discharged using only the airflow of the AOS. When the catalyst was saturated, the active oxygen was turned on and the odor was checked. The odor was almost no longer present, and the odor meter readings dropped significantly.

The catalyst used is a special catalyst that adsorbs OH very well.

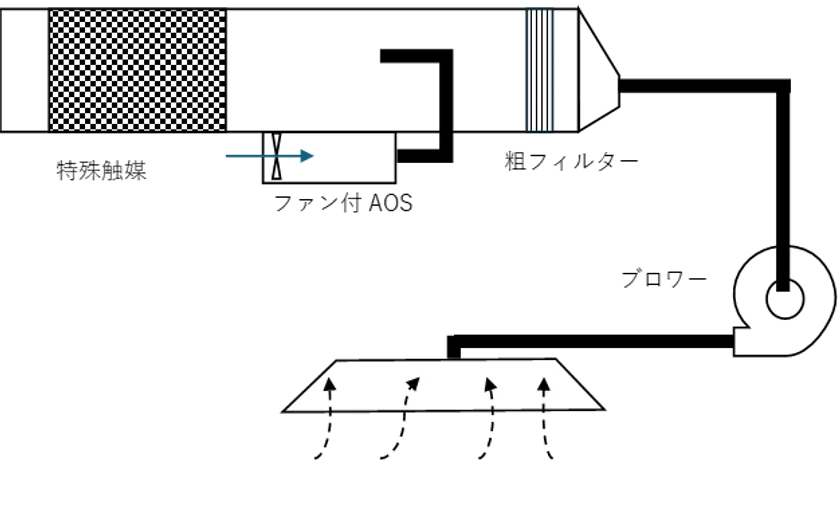

■Treatment equipment (actual equipment) plan

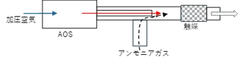

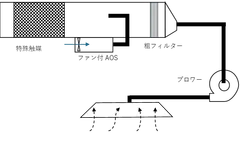

In the case of spot treatment equipment

The system is installed by suspending it from the ceiling at the site. Installation is done by hanging it from the ceiling at the site.

Image (3)Actual equipment (plan)

Summary

Possibility : 0 Theoretically and experimentally, NH3 can be decomposed by ・OH

Reaction speed: Moderate (slow in normal atmosphere, but fast under AOS)

Final products : Mainly N2 and water, secondary NOx/HNO3

Optimal conditions: Humid environment + high OH concentration (109-1012 molecules/cm3)

In the use of active oxygen + catalyst, all organic matter adsorbed by the catalyst is decomposed by the active oxygen, eliminating catalyst saturation and the need for replacement maintenance.

Currently, two companies have requested ammonia treatment, and we will provide equipment for each situation, as well as sell general-purpose equipment in the future.

Based on this knowledge, we will also develop in-plant VOC treatment equipment to enable air circulation and energy reduction from the situation where VOC treatment is not possible and all VOCs are discharged.

Company Profile

Company name: WEF Technology Development Co.

Representative: Akira Aoyama, Representative Director

Location: 1-19-15 Do, Otsu-shi, Shiga

Establishment : July, 2016

Business description: Development and sales of water treatment, waste recycling, and Mg-related technologies

URL : https://aoyama-wefit.com

https://mgwaorld.aoyama-wefit.com (Magnesium World)

- Category:

- Services