Aichi Kikai Techno Systems delivered unmanned automatic guided vehicle (AGV) for -25°C frozen warehouse to Hiroshima Branch of Kansai Frozen.

~Drastic improvement in work efficiency and safety in a frozen environment to promote logistics DX~.

Aichi Kikai Techno System Co., Ltd.

Aichi Kikai Techno System Co., Ltd. (Headquarters: Atsuta-Ku, Nagoya City, Aichi Prefecture; CEO: Kenichiro ITO) will deliver AGV that can handle at -25°C frozen warehouses for the relocation of the Hiroshima Branch (Hiroshima City) of Kansai Frozen Distribution Co., Ltd., a wholly owned subsidiary of Ezaki Glico Co., Ltd. By automating the transfer of heavy carts in a frozen environment and linking it with the Warehouse Execution System (WES), the AGV will significantly improve the efficiency of frozen warehouse operations, as well as reduce the workload of workers and improve safety.

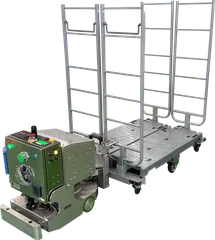

AGVs to be delivered

Low-temperature DB type

Background of Introduction

As the logistics industry faces a labor shortage and an aging population, working in a frozen warehouse at -25°C is a particularly harsh environment, and improving efficiency and ensuring safety have become urgent issues. In light of this situation, we provided Kansai Frozen proposal of next-generation logistics model that would break away from conventional manpower-dependent operations in frozen warehouses and achieve both efficiency and safety for Hiroshima Branch's relocation.

Outline of AGV Introduction

1. Joint development:

Kansai Frozen, which has expertise in the operation of frozen warehouses, and Aichi Kikai Techno System, which manufactures AGV (Automatic Guided Vehicle), combined their respective technologies and experience to develop specifications for a frozen environment together.

2. Technical innovations:

The battery is designed to maintain stable battery performance even in -25°C frozen environment.

Unique mechanism is incorporated to prevent sensor malfunction due to condensation or freezing.

3. Operational model:

By automatic synchronizing transfer and loading/unloading operations, we have created the system to work efficiently and safely in the freezer.

Effects of Introduction

○Improvement of the working environment through automation of transfer operations

Six AGVs will automate the work of towing heavy carts in -25°C environment, which was previously performed manually. This reduces the work time by approximately 4,928 hours per year (13.5 hours per day) and reduces the risk of back pain and frostbite of the workers.

○Improved work efficiency and reduced truck waiting time

Improved efficiency of transport operations reduces truck waiting time, and improves the ability to respond to shorten delivery times.

Linkage of AGV and Warehouse Execution System (WES)

This linkage automatically recalls the location information of the cart and transports it to the destination. And this solves "Person-dependent" relying on the tacit knowledge of veteran workers. Also this reduces the amount of time employees spend working in a frozen environment, and cerates more comfortable working environment.

○Reduction of shipping errors

By lowering the shipping error rate close to zero, we reduce work errors and improve logistics quality.

○Optimization of energy and operating costs

Automation of transport operations optimizes energy use and operating costs.

Future development

Starting with the introduction of this system, we will provide various proposals that can actively contribute to logistics DX in frozen warehouse operations, which had been considered difficult until now.

Company Profile

Company name: Aichi Kikai Techno Systems Co., Ltd.

Representative: Kenichiro ITO, Representative Director and CEO

Location: 1-10 Minamiichibancho, Atsuta-ku, Nagoya City, Aichi Prefecture

Establishment: October 1, 1998

Business : Design, manufacture and sales of AGVs and related equipment

Capital : 80 million yen

- Category:

- Corporate Trends