To achieve zero trouble and zero accidents even if you make a mistake We are always looking for participants for our prevention seminars

~ 90% of problems and accidents are caused by mistakes (human error).

未然防止研究所

Prevention Institute (Ota-ku, Tokyo; Representative: Akira Hayashibara), which provides consulting services for the prevention of problems and accidents, is working to spread "prevention" with the aim of realizing a society with zero problems and accidents.

We are always looking for companies that would like to participate in our seminars on proactive prevention.

We look forward to hearing from you.

Official website URL: https://www.mizenboushi.com/

Lecture Scene_Japan Standard Association

What is proactive prevention?

Prevention is the act of noticing future risks and taking countermeasures to prevent problems and accidents that may occur in the future.

Prevention is a process of recognizing future risks and taking countermeasures to prevent problems and accidents that may occur in the future.

Prevention is not a cost, but a management philosophy that should be practiced by managers, not just a method.

Current problems

How many problems(*) do you have in your workplace? How much time, effort, and cost do you spend to deal with these problems? If there were no problems, that time could be used for more positive work. This would increase employee motivation and contribute to improved company performance.

*Trouble covers customer complaints such as quality defects and late deliveries, internal problems such as work rework and wrong documents, accidents (work-related accidents), and scandals.

Are there any of the following problems in your workplace?

Are there any of the following problems in your workplace?

The same employees keep making mistakes (human errors).

Even if preventive measures are taken, the recurrence does not stop and similar problems occur.

The atmosphere in the workplace is poor and motivation is not maintained due to the continuous troubleshooting.

The company has implemented Hiyari-Hatto (near-miss) countermeasures and KYT (hazard prediction training), but minor accidents continue to occur at the work site.

Many companies make the following mistakes.

Many companies make the following mistakes: ・Is ISO 9001-certified, but they are so busy with the paperwork that they fail to improve the quality of their products.

The facts of the trouble are not correctly grasped.

The root cause of the problem is not properly understood.

The method of pursuing the root cause (true cause) is not understood in the first place.

Prevention of recurrence and prevention of recurrence are confused → Insufficient prevention of recurrence, and no efforts are made to prevent prevention of recurrence.

Seminars, Training, and Lectures

Seminars and training for companies (in no particular order)

Domestic: Murata Manufacturing Company, Mitsubishi Heavy Industries affiliate, mid-sized auto parts manufacturer,

Tokyo Electric Power Company affiliated company (IT-related), Sumitomo Chemical, Toray Engineering,

Major construction companies, Toyo Engineering Corporation, East Japan Railway Company, Tsukishima Machinery Co,

Panasonic labor union, Hitachi Construction Machinery, Kagome, major highway construction company,

Foreign medical equipment manufacturers, Mitsui Warehouse, Obayashi Corporation, Ajinomoto, etc.

Overseas: Automobile parts manufacturers (Europe, U.S., China, Thailand), major production equipment manufacturer (Austria)

2. open seminars (in no particular order)

Japanese Standards Association, Japan Management Association, Toshima Ethical Corporation Association, Information Organization of Japan, Japan Stationery Association, recruitment agencies, Osaka Industrial Association, local bank-related organizations, training companies, Asian Productivity Organization (held in Malaysia), etc.

Seminar Overview

All around us, various troubles and accidents occur. Each time this happens, there are calls for prevention of recurrence, but the recurrence never seems to stop. This is because "prevention" has not been achieved.

In this seminar, we will explain how to achieve zero occurrence of problems and accidents in the workplace, even if mistakes are made, through emergency response to problems and accidents, investigation of root causes to prevent recurrence, and risk awareness in prevention.

Seminar Participants

All departments, regardless of industry, are eligible for this seminar.

Young employees with high aspirations for management positions.

Comments from participants

Over 90% of the participants share their opinions and support for the seminar.

Please click on the URL below to read the testimonials of the participants. Please search for "Prevention: Testimonials" or "Prevention: Testimonials".

https://www.mizenboushi.com/customer-voice/

≪Proposed Program of the Seminar≫.

(Note: We will propose a unique program based on the requests of companies and industry associations.

≪Theory: What is proactive prevention?

1. current status of business-related troubles, scandals, and accidents

2. 90% of troubles and accidents are caused by human error (mistakes)

3. what is proactive prevention?

4. 3-Step Prevention Measures

4-1. 1st Step: Emergency Response

4-2. 2nd Step: Recurrence Prevention

4-3. 3rd Step: Prevention

≪Practical section: Specific measures for proactive prevention

1. business basics (for successful prevention activities)

2. creating an environment for proactive prevention

3. three essential prevention activities

4. best practices of prevention

5. work techniques useful for prevention

6 . 6. how to learn from failures and successes

≪Case Study Exercises and Q&A≫.

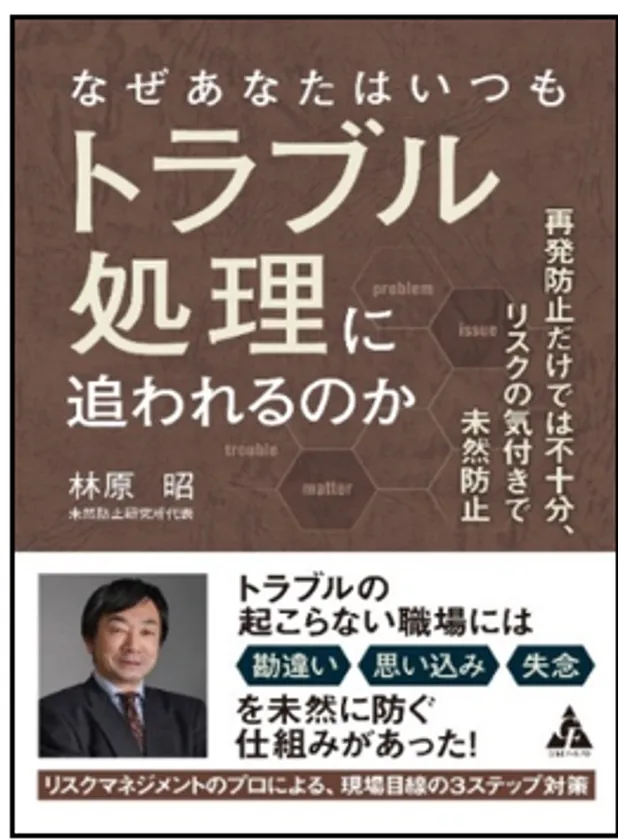

■ Book Publication

In August 2017, we published a book for business people (especially managers). This book provides concrete explanations with many case studies on how to make mistakes and prevent real and harmful business problems through teamwork.

Outline of the book

Name :Why are you always forced to deal with problems?

~Prevention of recurrence is not enough, preventing problems before they happen by recognizing risks.

Author :Akira Hayashibara

Release date: August 4, 2017

Publisher :Godo Forest

Book

[Index].

Chapter 1: What is Trouble Caused by Mistakes?

Chapter 2: Human Habits and Brain Habits that Trigger Mistakes

Chapter 3: Three steps to deal with problems caused by mistakes (emergency response, recurrence prevention, and proactive prevention)

Chapter 4: Implementation of preventive measures with the participation of the entire team

Chapter 5: Case studies of the 3 steps (emergency response, recurrence prevention, and proactive prevention)

Chapter 6: Improvement of prevention activities by improving the three capabilities

Resource section: Preventing problems by e-mail

Profile

Akira Hayashibara

Representative of the Prevention Research Institute, and a prevention consultant who aims to realize a society with zero problems and accidents.

After graduating from the Department of Instrumentation Engineering, Faculty of Engineering, Keio University, he joined Nissan Motor Co. Through productivity improvement activities at manufacturing sites, production management and logistics practices, and system development, he worked on business reform and improvement, and learned the importance of the workplace.

He then moved to Chiyoda Corporation, where he worked on an automobile plant construction project. Since 2000, he has been practicing "prevention" activities through quality assurance work, mainly in the automotive industry, and has laid the foundation for his current business.

Through his business experience in more than 30 countries in Japan, Europe, the U.S., and Asia, he has acquired the ability to adapt to different cultures and environmental changes, as well as business English.

In 2017, he published a book and started to promote "proactive prevention" activities, aiming for zero problems and accidents, and is currently practicing seminars, corporate training, lectures, and consulting activities.

Akira Hayashibara, President, Prevention Institute

Company Profile

Company name: Prevention Research Institute

Representative: Akira Hayashibara

Home Page: https://www.mizenboushi.com/

Business Description : Management Consultant (Prevention of business problems and accidents, quality improvement, cost reduction, supply chain management, and business continuity management)

Quality improvement, cost reduction, supply chain management,

Support for the launch of overseas factories and their operation, etc.)

- Category:

- Corporate Trends