The 2025 problem will increase the number of denture refugees! Dental laboratories are going digital Number of digital dentures produced reaches 1,000 in 3 years

株式会社お守り入れ歯

The 2025 problem is when the baby boom generation will be 75 years old or older. In the dental industry, it is expected that more people will not be able to make dentures in the future even if they want to due to the increase of underpopulated dental care districts and shortage of denture technicians. (Head office: Sapporo, Hokkaido; Representative Director: Akira Ikeda), which operates a dental laboratory, has been digitizing dentures since 2021 to improve the efficiency of dental treatment and denture fabrication by technicians. As of November 2024, 1,000 digital dentures have been produced.

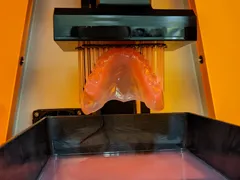

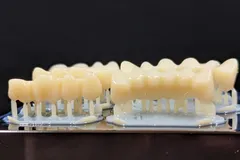

Digital denture fabrication. No plaster scraps, no mess, no contamination.

The time when dentures cannot be made even if you want to make them is just around the corner.

In the year 2025, the baby boomer generation will be over 75 years old, and it is expected that there will be a shortage in the workforce and a tightening of the medical care system. The dental industry has already begun to be affected by the shortage of dentists and technicians. Some technical schools have stopped accepting technicians, who make dentures and other products under the direction of dentists, due to a shortage of manpower and a decrease in the number of young people who want to become technicians, who value work-life balance.

On the other hand, as the population ages, more people will need dental care in the future as more people lose their teeth due to dental abscesses and cavities as they age. Technicians specialize in the production of silver teeth, implants, and dentures, but denture technicians require higher skills and experience. However, the number of dentists and denture technicians who focus on denture treatment is decreasing due to low reimbursement for the time and effort required. In 2040, when the baby boomers are expected to retire en masse, the number of people who cannot afford dentures is expected to increase, and there is an urgent need to establish a practice system that increases productivity by improving efficiency.

Digitalization of denture production has many advantages.

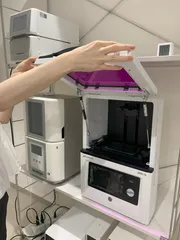

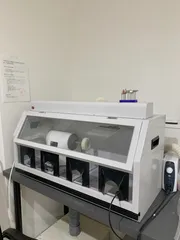

Ltd., which operates a dental laboratory, has been promoting the digitalization of dentures since 2021. We have partnered with dental clinics in Hokkaido and other parts of Japan, and have produced 1,000 digital dentures. Digital dentures are replicated at the laboratory using a 3D printer based on the shape data read by a 3D scanner or intraoral scanner at the dental clinic. We currently have one technician. We produce models and molds for the treatment process, spare dentures that scan and duplicate the exact same denture currently in use, and denture mouthpieces specially designed for nighttime use that are flexible and less stressful on the gums.

One of the benefits of digital dentures is a significant time savings. While a new denture takes about two months with multiple visits to the dentist, a full denture can be completed in as little as two to three days based on the data obtained. The process that used to take about 30 minutes to align the gums and teeth can be done with a single click. Next is the high accuracy. It is difficult to make exactly the same denture even if the same technician makes it, but with digital dentures, it is possible to make exactly the same denture in a short time. Digital dentures can be made in a shorter period of time, and the plaster scraps from grinding are less contaminating and polluting to the indoor air. The improvement of work efficiency is also expected to raise the retirement age of denture workers, which will lead to the resolution of the shortage of human resources in the future.

Currently, digital fabrication of dentures can be used to fabricate plastic parts, but the most popular partial dentures have metal fittings. The metal fittings are cast by molding and pouring metal one by one, which is a time-consuming and labor-intensive process. In the future, when digital fabrication of metal fittings becomes possible, it will further improve efficiency.

Dentures made with a 3D printer

Digital treatment of dentures is urgently needed, and insurance coverage is not progressing.

While the digitalization of dentures and implants has been progressing due to insurance coverage, the introduction of dentures has not progressed because they are still not covered by insurance. The increase in the cost to the patient and the high cost of purchasing equipment are the main reasons for the lack of progress. In particular, many dental clinics and laboratories are still unable to introduce the technology because they are privately owned or run on a small scale. We are working with such dental clinics to produce digital dentures.

Representative's voice: "Since the number of denture users is expected to increase inversely to the decrease in the working population in the future, we hope that digital denture treatment will be covered by insurance as soon as possible. If it is covered by insurance, the demand will increase and the digitalization of dentures will also progress. We also spoke with a person from Sapporo Dental Laboratory, a major laboratory that we have been doing business with for some time, who said that there is a lot of turnover in the workforce in their 30s, which is considered the prime working age, and that they feel the need to move quickly to digitalization. The low average annual salary and the imbalance between working hours are cited as issues, but if the number of productions increases through efficiency improvement, salary increases can be expected. Some laboratories have actually seen a drop in the turnover rate of workers in their 20s and 30s, so promoting digitization is a pressing issue for us as we look ahead to the future problems Japan faces."

One of our current digitization efforts, the free shape data storage "Denture Bank," has partnered with 20 dental clinics nationwide, and we will continue to develop this program to expand it throughout the country.

Omamori Dentures: https://omamoriireba.com/

Representative: Akira Ikeda, Omamori Dentures Co.

Company Profile

Company name: Omamori Dentures Co.

Representative Director: Akira Ikeda

Name of laboratory: Digital Denture Lab.

Business : Operation of denture bank, denture manufacturing, denture cleaning, antibacterial treatment

Address: Tomii Building No.37 5F, 3-12-2 Minami 2-jo Nishi, Chuo-ku, Sapporo, Hokkaido 060-0062, Japan

Phone number : 011-596-8814 (Office hours: 9:00-18:00 weekdays)

Business hours : Weekdays 9:00-18:00 (Closed on Saturdays, Sundays, and national holidays)

- Category:

- Corporate Trends